What is CNC Machining?

What is CNC Machining?

CNC (Computer Numerical Control) machining is a manufacturing process where pre-programmed computer software dictates the movement of factory tools and machinery. This process enables the production of precise parts by removing material from a workpiece using various cutting tools.

CNC Machining Process Steps

- Design Creation: Engineers design the part using CAD (Computer-Aided Design) software.

- Programming: The design is converted into a CNC program using CAM (Computer-Aided Manufacturing) software, generating G-code.

- Machine Setup: Operators set up the machine, securing the workpiece and installing the appropriate tools.

- Machining: The CNC machine executes the program, performing the necessary cuts and movements.

- Quality Control: Finished parts are inspected for accuracy and quality.

Types of CNC Machining Operations

- Milling: Rotating cutting tools remove material to shape the workpiece.

- Turning: The workpiece rotates while a stationary cutting tool shapes it.

- Drilling: Creating round holes in the workpiece.

- Boring: Enlarging existing holes with precision.

- Grinding: Using an abrasive wheel to achieve fine finishes.

- Cutting: Separating material using various methods like laser or plasma cutting.

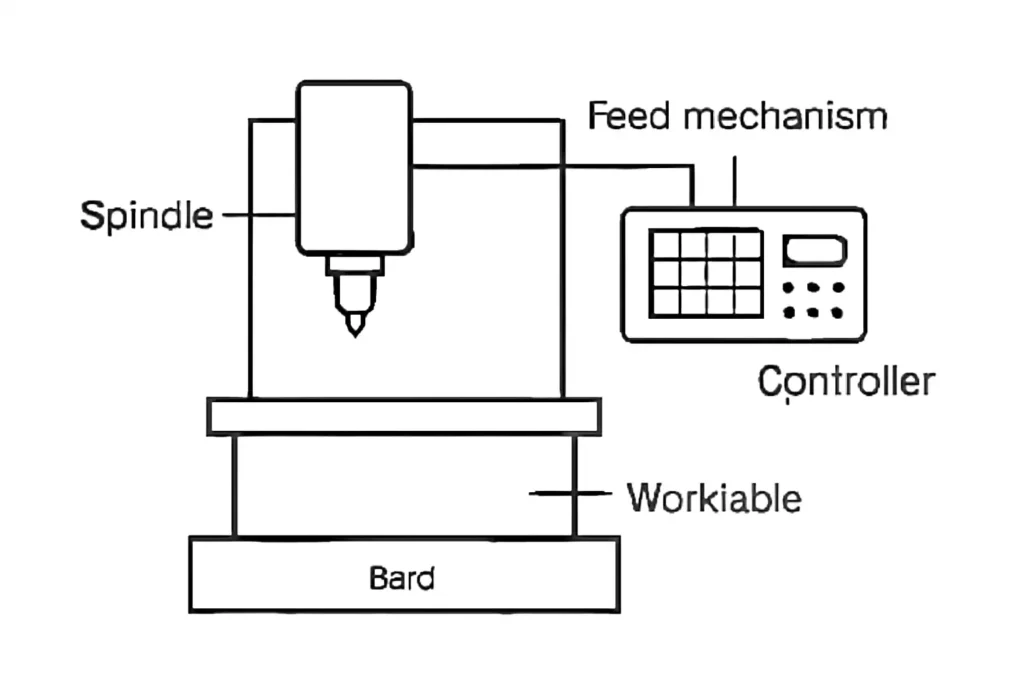

CNC Equipment and Key Components

- CNC Machine: Includes the bed, spindle, axes, and tool changer.

- Controller: The computer system that interprets G-code and controls machine movements.

- Axes: Typically X, Y, and Z axes, allowing multi-directional movement.

- Spindle: Rotates the cutting tool at various speeds.

- Tool Magazine: Stores multiple tools for automatic changing.

- Fixtures: Secure the workpiece during machining.

CNC Programming

CNC programming involves writing code (G-code and M-code) that directs the machine’s operations. G-code controls movements, while M-code manages auxiliary functions like coolant flow.

Looking for CNC machines built to handle graphite dust?

Explore Dust-Proof CNCsRecommended Machines for Graphite Machining

GraphiteCNC X1

Compact design, sealed chamber, HEPA filtration—ideal for precision graphite parts.

Learn More →