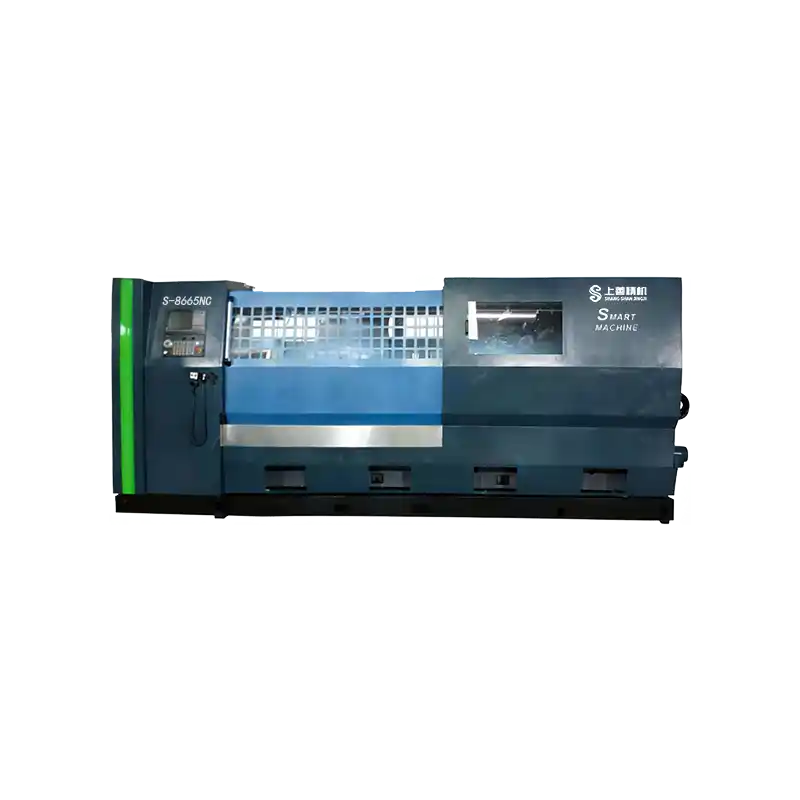

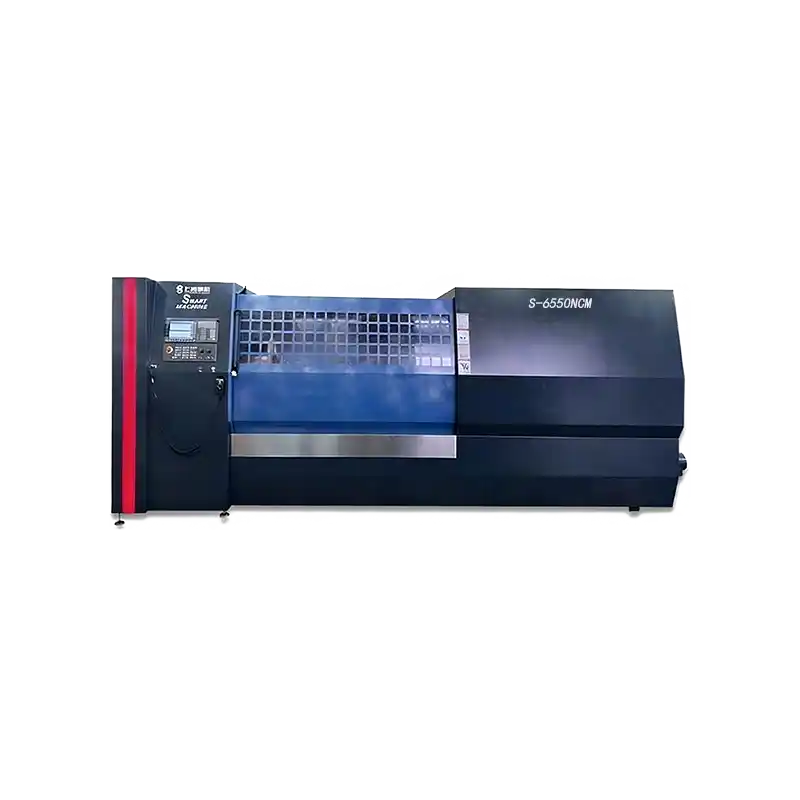

product Products Show

Guangdong Shangshan Jing Jii Co., Ltd.

Mr. Ma

+86 135 1010 9008

sales@ssjjchina.com

Guangdong China

现在提交需求 我们可为您专业提供定制生产

Customized Solutions for Your Need!

Global Inquiry Hotline:

Moblie:+86 13510109008

Email:sales@ssjjchina.com

Customized Factory Gallery

A professional manufacturer of ceramic processing machine tools, specialized in R&D and production, achieving a machining precision of ±0.005mm.

Project process Service Process

- Contact Us

- Requirement Consultation

- Customization

- Production

- Transportation

- Acceptance

- After-sales Maintenance & Service

查看更多+

Company Profile / New Products

About us Shan Shan Jing Ji

ABOUT US Shan Shan Jing Ji

View More+ 查看更多+

Blogs Center / Blogs

news Blogs

-

2026-01-14 05:53:30暂无文章

-

2026-01-13 05:53:30暂无文章

-

2026-01-12 05:53:30暂无文章

-

2026-01-11 05:53:30暂无文章

-

2026-01-10 05:53:30暂无文章

-

2026-01-09 05:53:30暂无文章

-

2026-01-08 05:53:30暂无文章

-

2026-01-07 05:53:30暂无文章

-

2026-01-14 05:53:30None

-

2026-01-13 05:53:30None

-

2026-01-12 05:53:30None

-

2026-01-11 05:53:30None

-

2026-01-10 05:53:30None

-

2026-01-09 05:53:30None

-

2026-01-08 05:53:30None

-

2026-01-07 05:53:30None

F&Q / Common problem

- 分类 "F&Q" 中暂无文章请在该分类下添加文章后刷新查看。

客服1

客服1  客服2

客服2